Not all pneumatic fittings are created equal. Each manufacturer designs fittings with slightly different dimensions, wall thicknesses, or weights — sometimes to reduce costs. While these differences may look minor, they can significantly impact performance and reliability over time.

At Ideal Bell, we believe quality begins with precision. Our pneumatic fittings are designed with stronger bodies and heavier structures than many low-cost alternatives to ensure better flow rate, durability, and stability in demanding pneumatic systems.

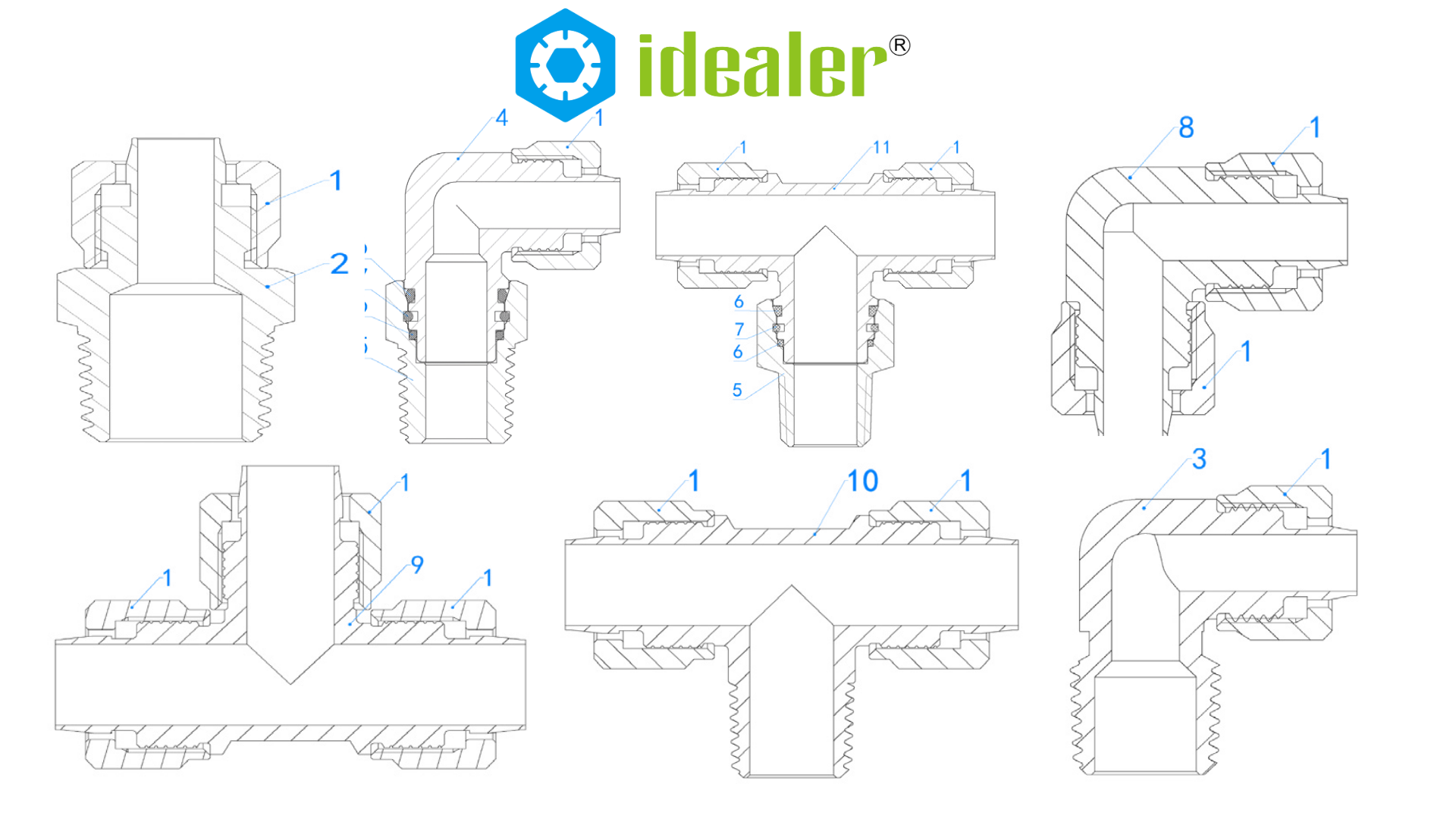

Bigger Size, Better Performance

Take the example of our IDEALER speed controller.

Both our version and another manufacturer’s are designed for 4mm OD air tubing, yet the difference is clear — ours is larger and more robust. This extra material means greater airflow capacity, longer service life, and improved resistance to vibration and pressure.

Why “Cheaper” Isn’t Always Better

Some suppliers minimize dimensions and use thinner materials to achieve a lower price. While it may look like a good deal, this often results in:

-

Lower pressure resistance

-

Increased leakage risk

-

Shorter lifespan under industrial conditions

In pneumatic systems, these small compromises can lead to big problems.

Our Commitment to Quality

At Ideal Bell, we always aim to keep our products cost-efficient — but never at the expense of quality.

We welcome customers to visit our factory to see our production, testing, and quality control processes in person.

For those who cannot visit, we’re glad to share:

-

Official third-party testing reports

-

Material certifications

-

Performance testing videos

If you want reliable pneumatic fittings that combine quality, safety, and value — contact us at sales@ideal-bell.com or leave us a message.

Ideal Bell – Committed to Quality You Can See and Feel.